Fast Lead Times: How 3D Printing Shortens Delivery Times

Waiting for parts costs money. Discover how 3D printing drastically reduces lead times - from weeks to days. Same-week delivery for businesses.

Dennis

3Dennis

Contents

Every day you wait for a part costs money. Idle machines, delayed projects, missed deadlines - the costs of long lead times are often higher than the price of the part itself.

At 3Dennis, we understand that time is money. That’s why we’ve optimized our process for speed without compromising quality. In this article, we explain how we shorten lead times and what this can mean for your business.

The problem with traditional lead times

The industry standard

Ask a traditional supplier about lead time and you get answers like:

- CNC milled part: 2-4 weeks

- Injection molded part: 6-12 weeks (including mold)

- Laser cut part: 1-3 weeks

- Sheet metal: 2-4 weeks

These aren’t exceptions but standards. The industry is set up for these timelines, and customers have accepted them as normal.

The hidden costs of waiting

But what does that waiting actually cost?

Downtime costs - A production machine waiting for a replacement part easily costs hundreds of euros per hour in lost production.

Project delays - A product launching two weeks late because a component wasn’t on time misses two weeks of revenue.

Inventory costs - To compensate for long lead times, companies maintain large inventories. That capital is tied up and must be stored.

Opportunity costs - The deals you don’t close because you can’t deliver fast enough.

How 3D printing changes this

No tooling, no waiting

The biggest difference is the absence of tooling phases. With traditional manufacturing, a mold or fixture must first be made. This alone takes weeks.

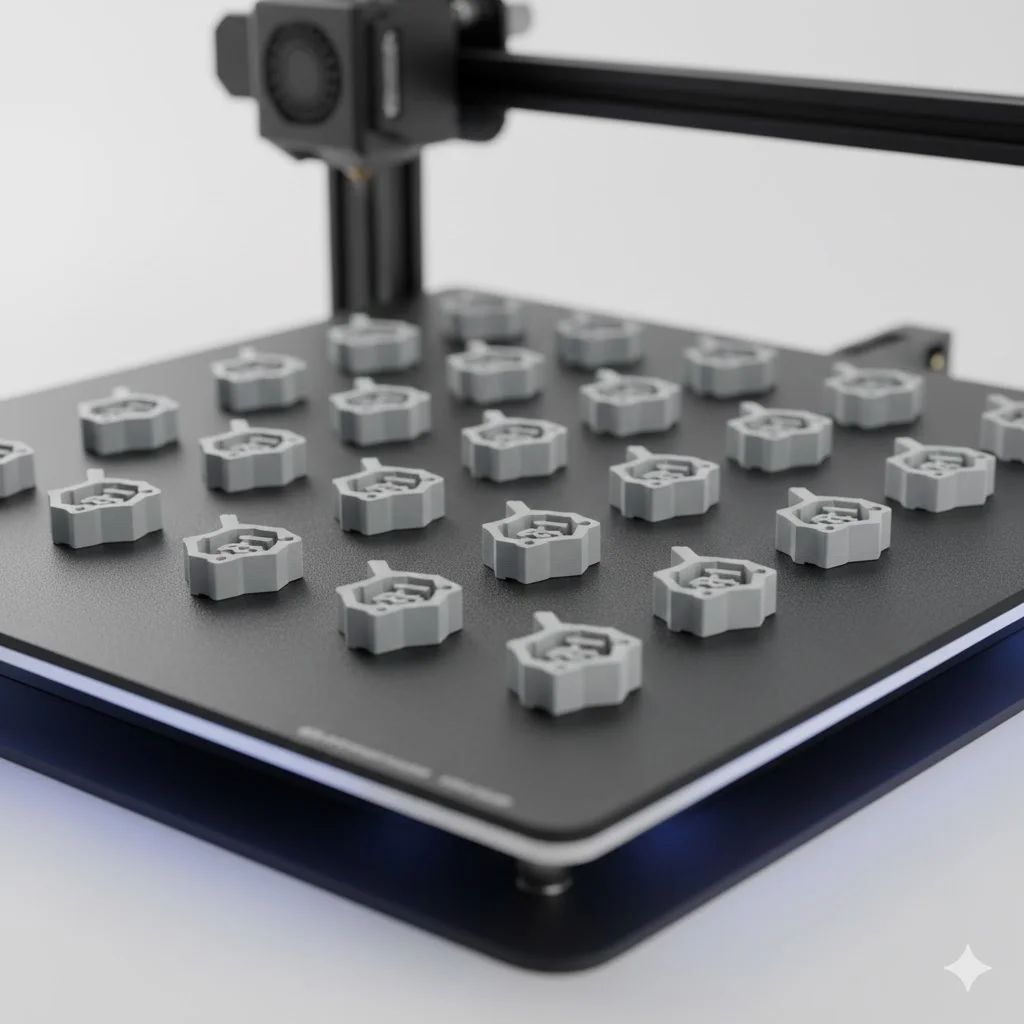

With 3D printing, the CAD file is directly the production instruction. Upload, slice, print. The time from file to physical part is the print time plus a bit of preparation.

Parallel production

We run multiple printers simultaneously. An order of 50 parts we split across 5 or 10 machines working in parallel. This compresses turnaround time enormously.

No minimum setup

There’s no startup cost requiring large batches. Whether you need 1 part or 100, we can start immediately. No waiting until an order is “big enough.”

Our lead time guarantees

Standard: 5-7 business days

Most orders we deliver within a week. This includes:

- Intake and model check

- Production planning

- Printing

- Post-processing

- Quality control

- Shipping

For the average order, this is more than sufficient, and it keeps costs reasonable.

Express: 2-3 business days

Need it faster? With express production, we move your order to the front of the queue. Priority on machines, accelerated post-processing, express shipping.

This costs extra, but when speed is crucial, it’s worth the investment.

Same-day/Next-day: on request

For true emergencies, we offer same-day and next-day production. We start immediately after approval, run evenings and nights, and ship by courier.

This is our premium service for critical situations. Costs are significant, but sometimes there’s no alternative.

Practical examples

The idle machine

A food processing company had a critical machine part break. The original supplier had six weeks lead time. Six weeks of downtime wasn’t an option.

They sent us the broken part on Tuesday. We reverse-engineered it, printed it in food-safe material, and delivered on Thursday. The machine was running again, loss limited to two days instead of six weeks.

The product launch

A startup had a launch planned, but discovered a design flaw in the enclosure two weeks before the deadline. Their Asian supplier couldn’t deliver in time.

We produced 150 improved enclosures in five days. The launch went ahead as planned.

The trade show presentation

An engineering company needed to present a working prototype at a trade show. The prototype was almost ready, but a final iteration was needed after internal tests.

Friday they discovered the problem. We printed through the weekend. Monday morning the new prototype was ready for the show that started Tuesday.

Tips to optimize lead times

Provide complete information

Incomplete orders cost time. Make sure your quote request includes:

- 3D model in STL or STEP format

- Material preference

- Desired quantity

- Deadline if relevant

The more complete, the faster we can start.

Design for printability

Designs requiring lots of support or complex post-processing take longer. Discuss design optimizations beforehand that can shorten turnaround time.

Plan ahead where possible

Express production is more expensive. By planning ahead, you can use standard lead times and save costs. We’re happy to help think about production schedules that balance speed and cost.

Keep a buffer

For critical parts, it’s smart to maintain a small inventory. We can deliver a monthly batch that you keep in stock, so you’re never without.

Lead time comparison

| Production method | Typical lead time | Our 3D print lead time |

|---|---|---|

| CNC milling | 2-4 weeks | 5-7 days (standard) |

| Injection molding | 6-12 weeks | n/a (no tooling) |

| Laser cutting | 1-3 weeks | n/a |

| 3D printing elsewhere | 1-2 weeks | 2-3 days (express) |

The value of speed

Fast lead times aren’t just convenience - they have hard economic value.

Lower inventory costs - Less capital tied up in inventory.

Higher machine uptime - Less downtime waiting for parts.

Faster product development - More iterations in less time.

Better customer service - Respond faster to customer needs.

Competitive advantage - Deliver faster than your competitors.

Getting started

Are you waiting on parts right now? Have projects delayed by long lead times? We can help.

Request a rush quote and we’ll respond within hours. Describe your situation, share the urgency, and we’ll find the fastest solution together.

Or contact us to discuss how we can structurally shorten your lead times. A dedicated point of contact, insight into our planning, and priority when you need it.

Speed is our standard. Let us prove what we can do.

Keep reading

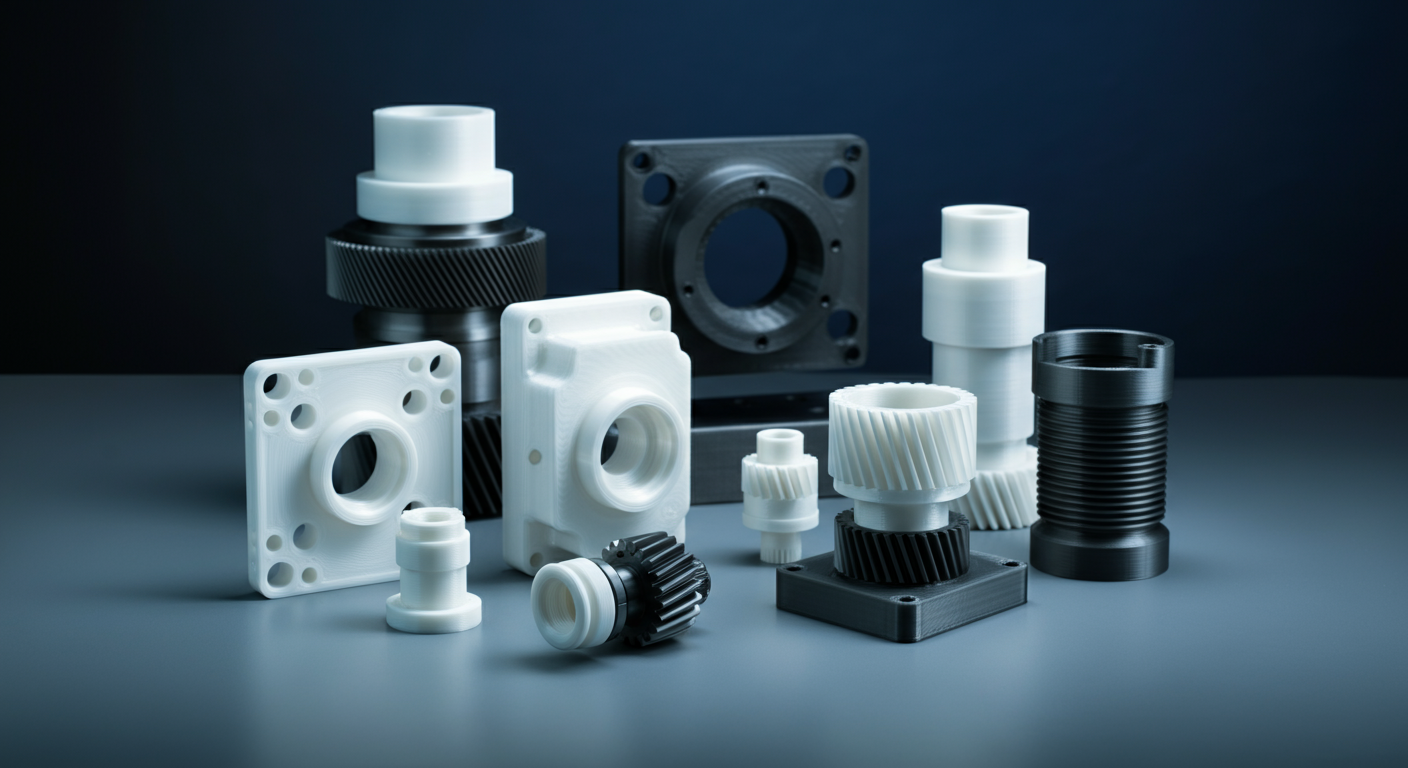

End-Use Production Parts: When 3D Printing Replaces Traditional Manufacturing

Discover how businesses use 3D printed end-use parts in production. From material advances to real cost benefits — why 3D printing is no longer just for prototypes.

B2B 3D Printing: How Businesses Save Time and Money with Custom Parts

Discover how businesses save costs with 3D printed parts. From prototypes to production runs - the business benefits of 3D printing explained.

Batch 3D Printing for Businesses: Producing Small Runs Efficiently

How does batch 3D printing work? Discover the advantages of series production with 3D printing for businesses. From 10 to 1000 pieces - efficient and affordable.

Need help with your project?

Contact us for custom 3D prints or B2B services.