Batch 3D Printing for Businesses: Producing Small Runs Efficiently

How does batch 3D printing work? Discover the advantages of series production with 3D printing for businesses. From 10 to 1000 pieces - efficient and affordable.

Dennis

3Dennis

Contents

You have a product you need in small quantities. Not one prototype, but 50, 100, or maybe 500 pieces. Too few for injection molding, too many to make by hand. This is exactly where batch 3D printing excels.

At 3Dennis, we produce batches for business clients daily. In this article, we explain how batch 3D printing works and when it’s the best choice for your production.

What is batch 3D printing?

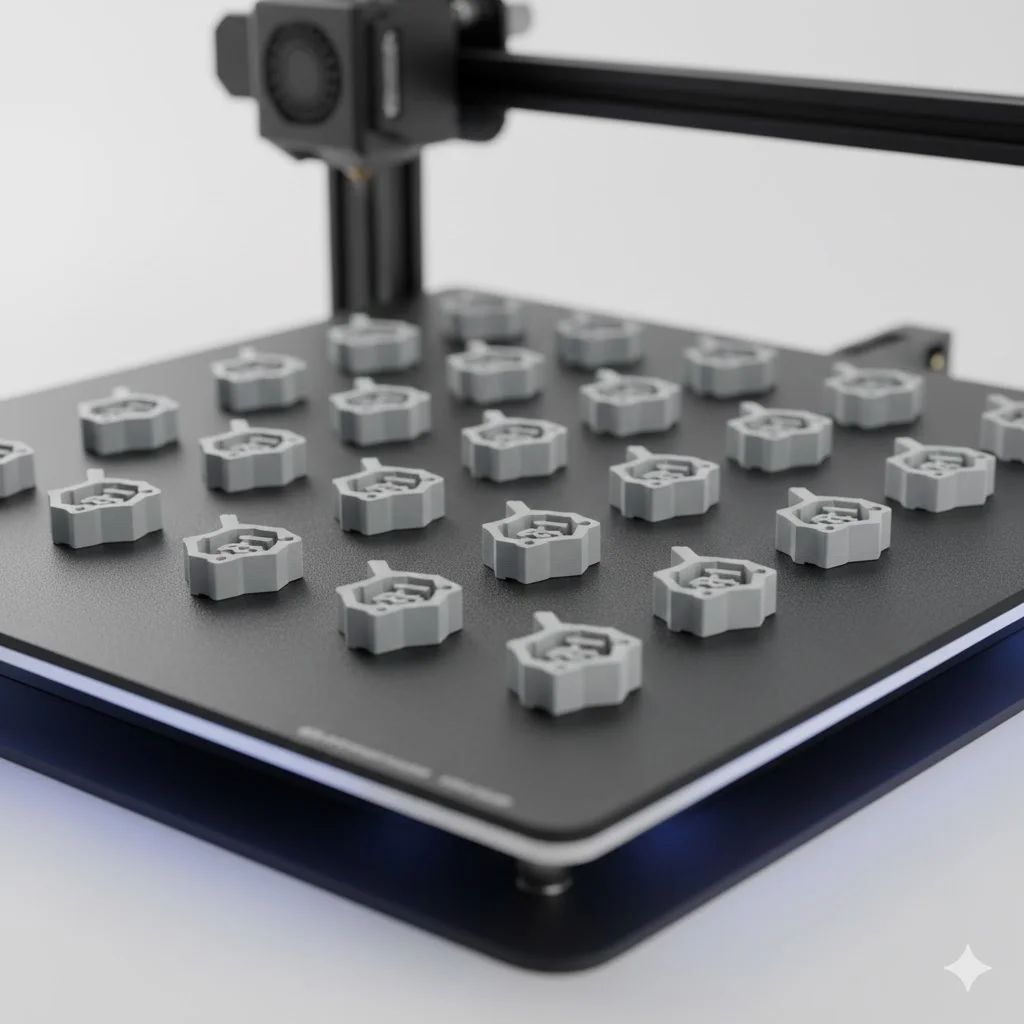

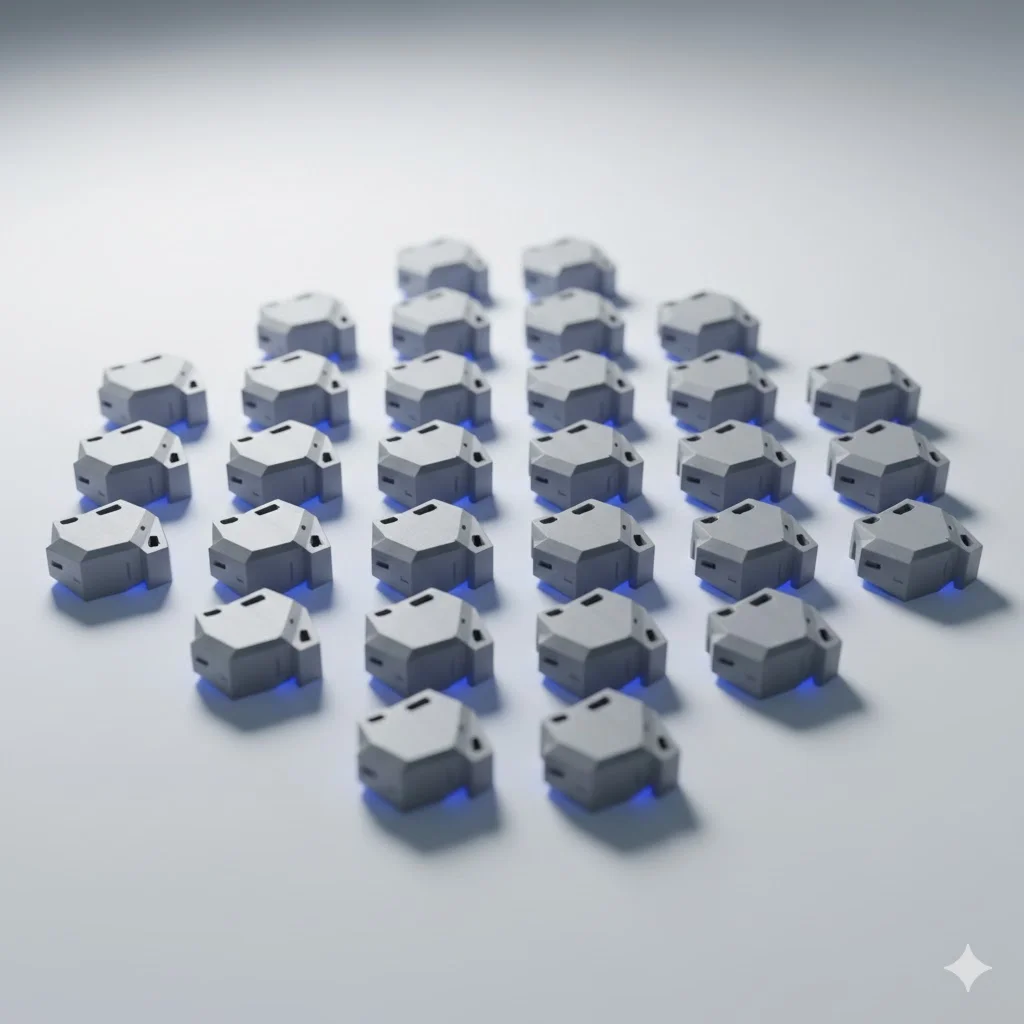

Batch 3D printing simply means producing multiple identical or similar parts in an organized production run. Instead of one print at a time, we fill the print bed with as many parts as possible and run multiple printers in parallel.

The economics of batches

With 3D printing, costs per part are relatively constant regardless of quantity. This differs fundamentally from traditional manufacturing where unit price drops as volume increases (due to tooling and setup costs).

Still, there are efficiency advantages with batches:

One-time setup - Preparing a print (slicer settings, positioning, quality check) is done once per batch, not per part.

Print bed optimization - Multiple parts on one bed is more efficient than separate prints. The printer starts once, doesn’t need to re-adhere repeatedly, and maximally uses available space.

Parallel production - With multiple printers, we run batches simultaneously. 10 printers means 10x the production capacity.

When is batch 3D printing the right choice?

The ideal volume: 10 to 1000 pieces

The sweet spot for batch 3D printing lies between 10 and 1000 pieces. Under 10 is often just custom work. Above 1000, injection molding may become interesting, depending on complexity.

In this middle ground, 3D printing is often the most economical and practical choice:

- No tooling costs

- Short lead time

- Flexibility to modify mid-run

- No minimum order requirements

Typical B2B applications

Product launches - Testing a new product with an initial run of 100 pieces before investing in mass production.

Seasonal products - Products you only sell part of the year and don’t want to stock in large quantities.

Custom products - Variants of a base product for different customers or applications.

Spare parts - Replacement parts for machines or equipment, produced on order.

Marketing and trade shows - Personalized giveaways or demonstration models for events.

How does our batch process work?

Step 1: Quote and planning

You send us your 3D model (STL or STEP) and desired quantity. We create a quote including material advice and lead time. Upon approval, we schedule production.

Step 2: Production optimization

Our team optimizes the print setup for maximum efficiency:

- Part orientation for best quality

- Nesting on the print bed for minimal print time

- Material and settings selection

- Distribution across printers for fastest turnaround

Step 3: Controlled production

During the batch, we monitor quality. First prints are inspected before we continue. Any deviations are addressed immediately. This prevents losing an entire batch to an undetected problem.

Step 4: Post-processing and QC

After printing comes post-processing if needed (support removal, surface treatment) and final inspection. Each part is visually inspected before packing.

Step 5: Delivery

The batch is carefully packaged and shipped. For large quantities, we deliver on pallets; for smaller volumes, via parcel service.

Practical examples

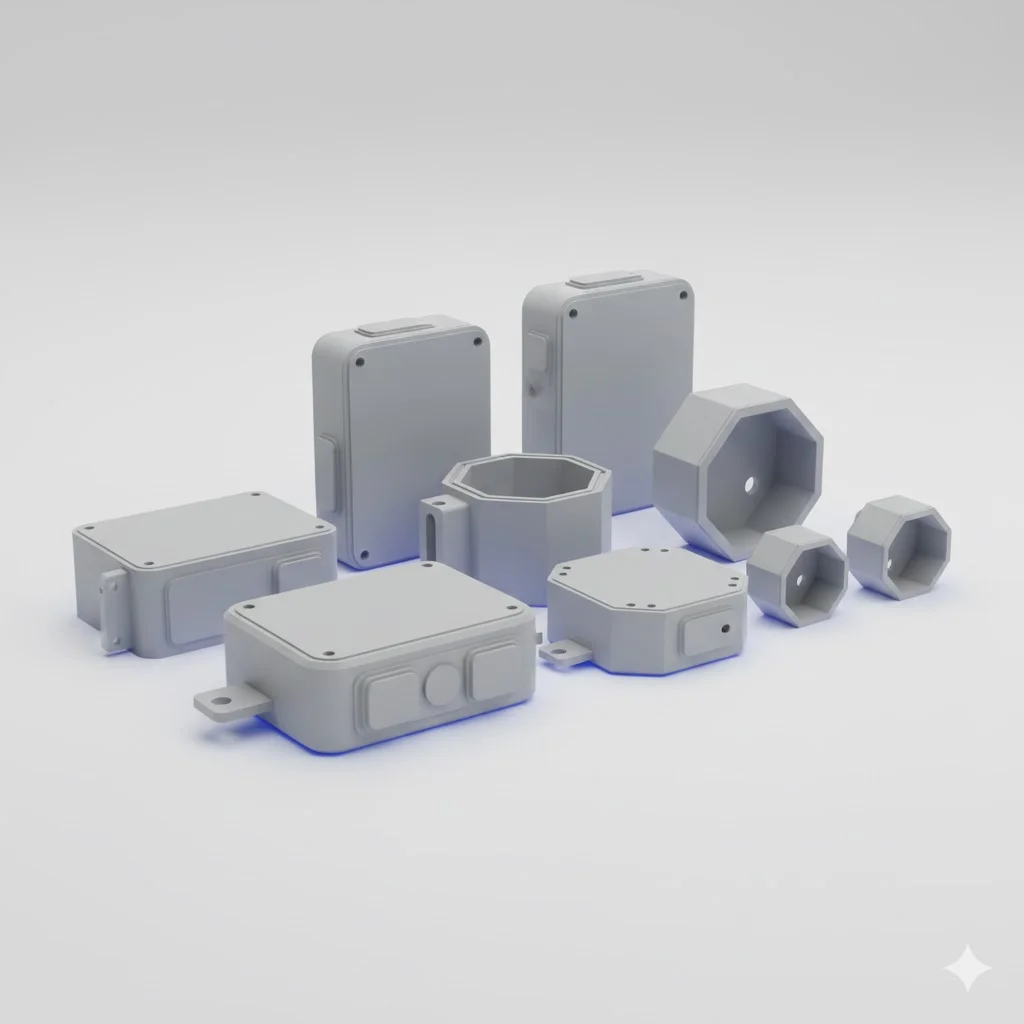

Case 1: Product enclosures for IoT startup

A startup developed an IoT sensor for the agricultural sector. They needed 200 enclosures for a pilot project. Injection molding wasn’t an option - the €12,000 mold cost couldn’t be justified for a pilot.

We produced the 200 enclosures in PETG within two weeks. Total cost: a fraction of what the mold alone would have cost. The pilot was successful, and we’re now working on the fifth batch.

Case 2: Monthly spare parts production

A machine builder has a maintenance program for their installed machines. Monthly, we produce a batch of replacement parts they keep in stock for fast service.

It involves 15 different parts, each in quantities of 10-50 pieces per month. We manage the entire production: they send a monthly purchase order, we deliver on the agreed date.

Case 3: Personalized products

A marketing agency ordered 500 phone holders with company logo for a client. Each copy with the same logo, but we could easily make variants for different events.

The flexibility of 3D printing made it possible to produce part of the batch in other colors when the client later requested it.

Pricing structure for batches

Fixed costs

- Model preparation and slicer setup (one-time per batch)

- Quality control

Variable costs per piece

- Material costs (grams of filament × price per gram)

- Print time (hours × machine hourly rate)

- Post-processing if applicable

Volume tiers

At larger quantities, cost per piece drops slightly due to more efficient production. Our quotes are transparent: you see exactly where costs come from.

Tips for efficient batches

Design for batch production

Some design choices make batch production more efficient:

Minimize support - Support costs material and post-processing time. Design with the 45-degree rule in mind.

Stackable design - Parts that can be nested (fit inside each other) utilize the print bed better.

Consistent wall thickness - Prevents warping problems with larger batches.

Plan ahead

Last-minute batches are possible but more expensive. With advance planning, we can produce more efficiently and offer better rates.

Consolidate orders

Need multiple parts? Combine them in one order. This saves setup time and shipping costs.

Comparison with alternatives

| Aspect | Batch 3D | Injection Molding | CNC |

|---|---|---|---|

| Tooling costs | None | High | Low |

| Cost at 100 pcs | Favorable | Very high | High |

| Cost at 10,000 pcs | High | Favorable | High |

| Lead time | Days | Weeks/months | Weeks |

| Design freedom | High | Limited | Limited |

| Changes | Simple | New mold | New program |

Getting started with batch 3D printing

Batch 3D printing is ideal for businesses needing small to medium runs without the costs and lead time of traditional manufacturing.

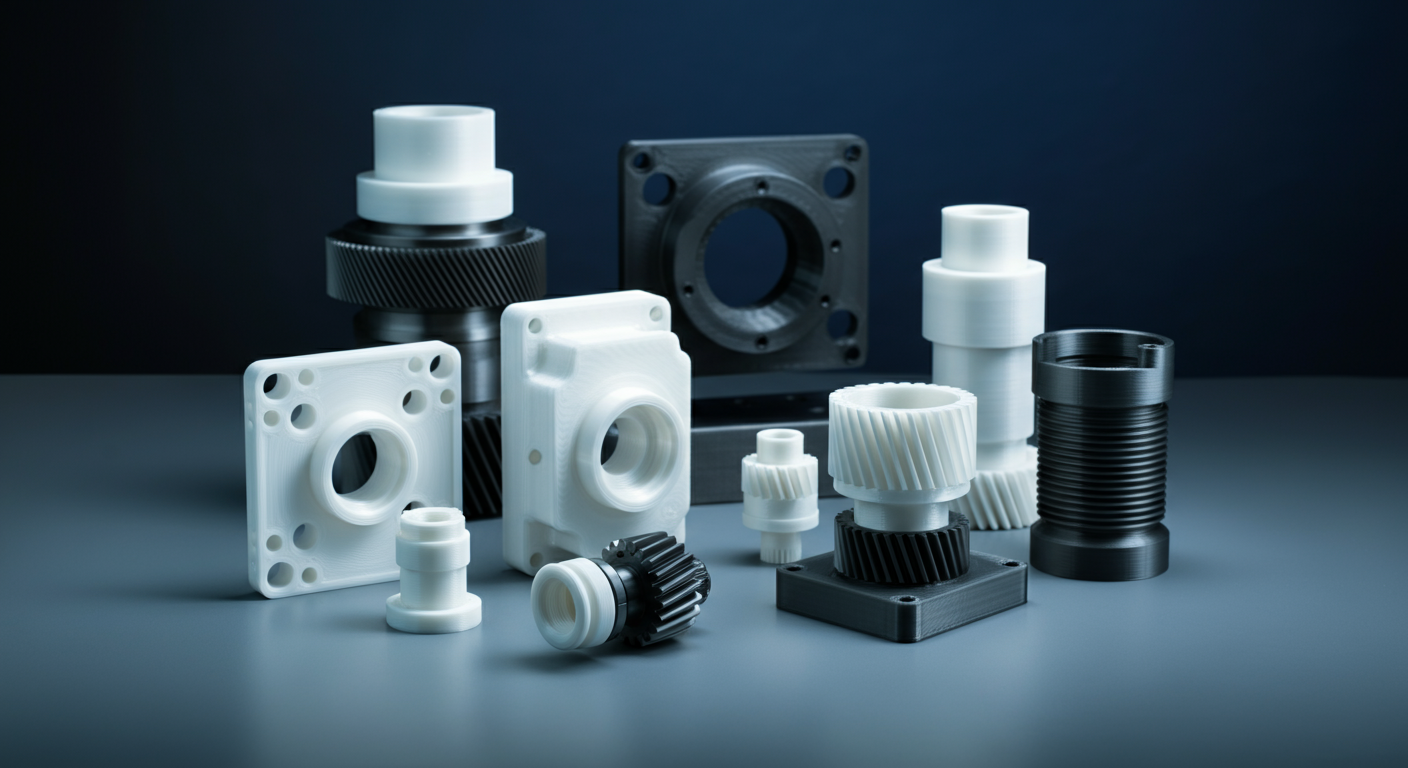

At 3Dennis, we have the capacity, experience, and processes to produce batches efficiently. From 10 to 1000 pieces, in materials from PLA to engineering plastics.

Request a quote for your next batch, or discuss your production planning with us. We’re happy to explore the optimal approach for your situation.

Keep reading

B2B 3D Printing: How Businesses Save Time and Money with Custom Parts

Discover how businesses save costs with 3D printed parts. From prototypes to production runs - the business benefits of 3D printing explained.

End-Use Production Parts: When 3D Printing Replaces Traditional Manufacturing

Discover how businesses use 3D printed end-use parts in production. From material advances to real cost benefits — why 3D printing is no longer just for prototypes.

Custom Enclosures: 3D Printing vs Injection Molding - The Honest Comparison

When do you choose 3D printed enclosures and when injection molding? A practical comparison of costs, lead times, and quality for businesses.

Need help with your project?

Contact us for custom 3D prints or B2B services.