B2B 3D Printing: How Businesses Save Time and Money with Custom Parts

Discover how businesses save costs with 3D printed parts. From prototypes to production runs - the business benefits of 3D printing explained.

Dennis

3Dennis

Contents

More and more businesses are discovering 3D printing as a strategic tool for faster and cheaper production. What was once a hobbyist’s toy has grown into a serious manufacturing technology that beats traditional methods on multiple fronts.

At 3Dennis, we work daily with businesses of all sizes. In this article, we share how they use 3D printing and the benefits they experience.

The problem with traditional manufacturing

Traditional manufacturing methods like injection molding and CNC machining are fantastic for high volumes, but have significant drawbacks for smaller quantities or custom work.

The cost of injection molding

An injection mold costs anywhere from €5,000 to €50,000 or more, depending on complexity. That investment needs to be recouped over your production run. At 10,000 units, no problem. At 100 units, each part becomes unaffordable.

Add to that: every design change requires a new mold. During product development, when designs change frequently, this is an enormous cost burden.

Long lead times

Ordering a new injection mold means waiting weeks to months. In a market where speed matters, this is a serious disadvantage. CNC parts are faster but still significantly slower than 3D printing.

How 3D printing solves this

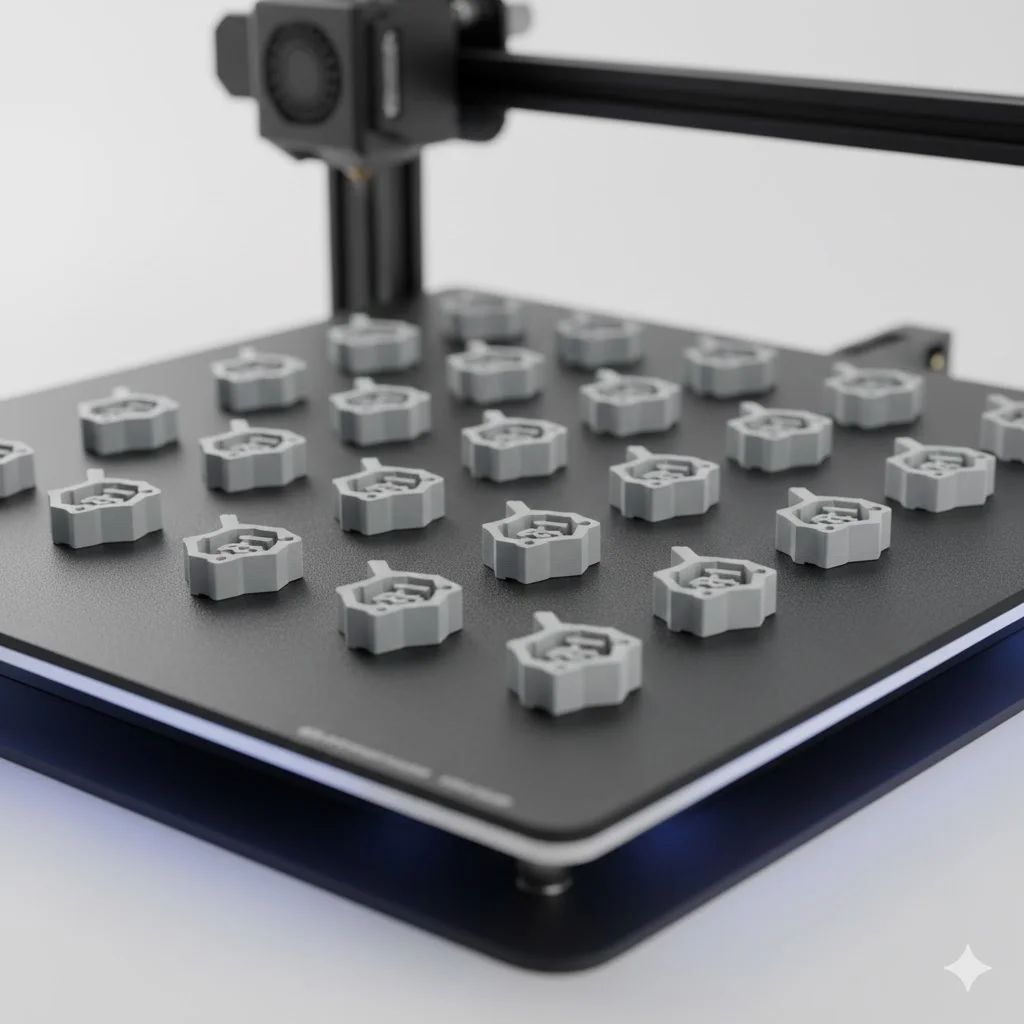

3D printing flips traditional manufacturing economics. There are no tooling costs, lead times are short, and small quantities are just as viable as large ones.

No fixed costs

With 3D printing, you only pay for material and print time. Whether you order 1 part or 100, the price per unit stays relatively constant. This makes small runs suddenly economically feasible.

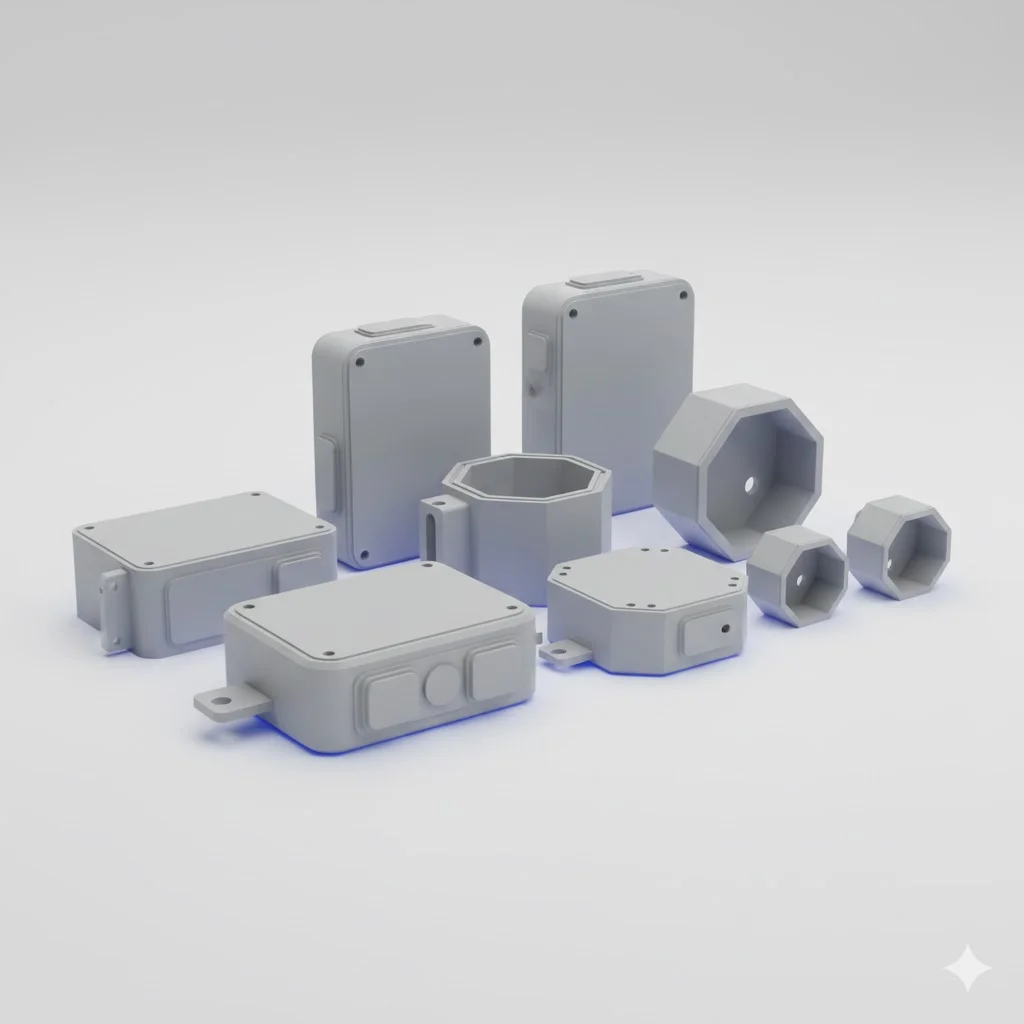

A concrete example: a client needed 50 custom enclosures. With injection molding, the mold alone would cost €15,000, plus production. We delivered the same parts in PETG for a fraction of that cost, ready within a week.

Speed that makes the difference

From design to physical part in days instead of weeks. This fundamentally changes how businesses can develop products and solve problems.

A machine builder in the industrial sector told us they used to wait weeks for replacement parts. Now they print critical components same-day and minimize their downtime.

Unlimited design freedom

3D printing enables shapes that are difficult or impossible with traditional methods. Internal channels, organic structures, integrated hinges - it all prints in one go.

This opens doors for lighter, stronger, and more functional designs that simply weren’t manufacturable before.

Concrete applications in business

Prototyping and product development

This is where most businesses start with 3D printing. The ability to adjust a design in the morning and hold it in your hands by afternoon is transformative for product development.

A design agency we work with prints an average of three iterations per week for new products. In the time they used to get one physical prototype, they now test ten variations and arrive at a better end product faster.

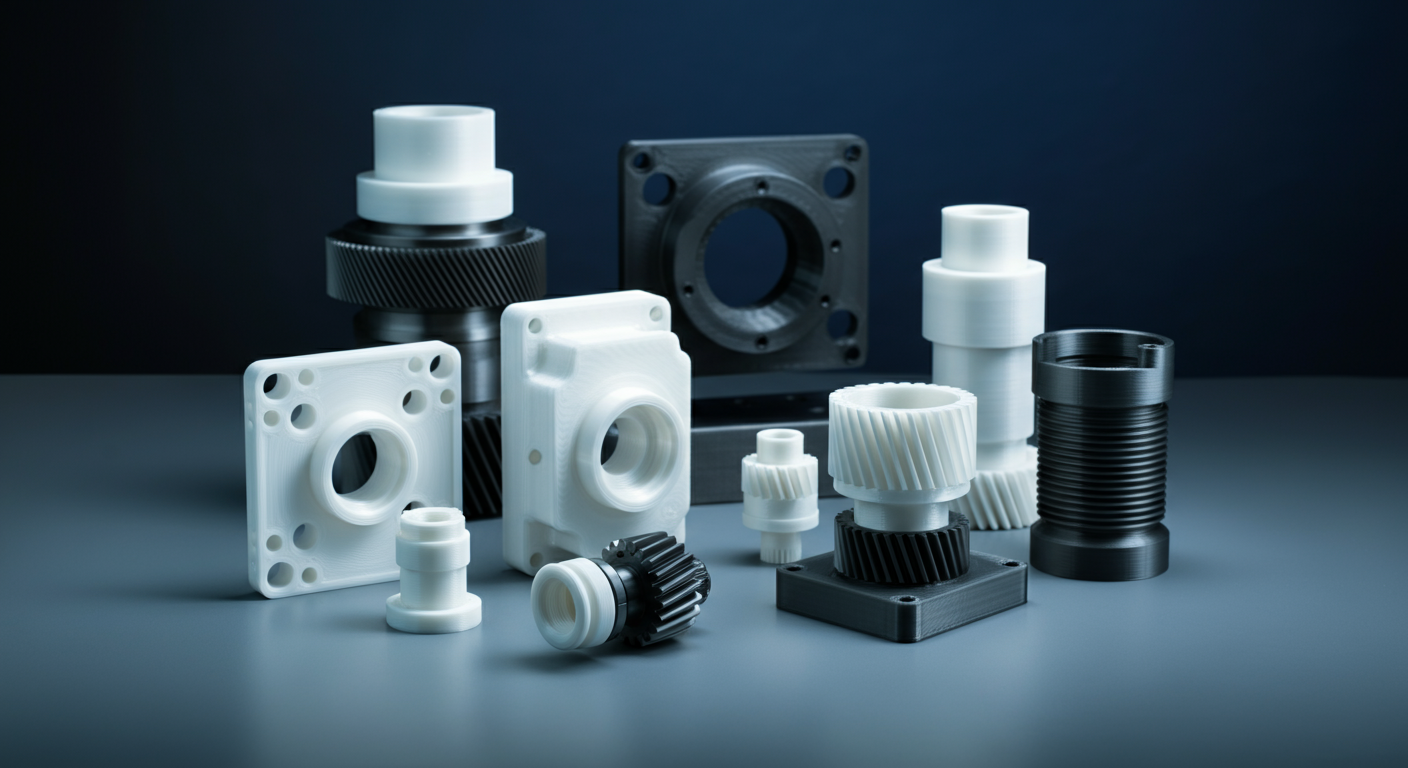

Functional end products

3D printing is no longer just a prototyping technology. With the right materials and settings, 3D printed parts work as final products.

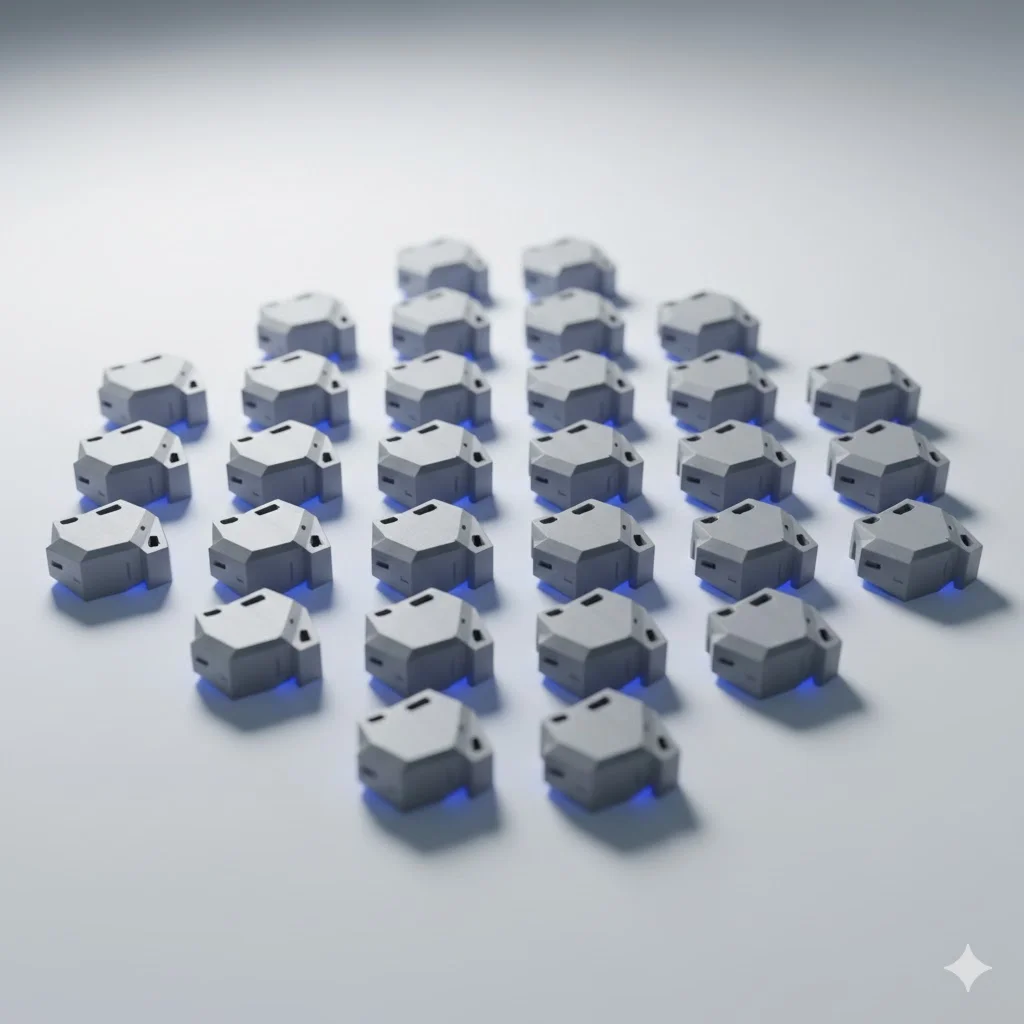

At 3Dennis, we deliver mounting solutions and enclosures that run for years in production environments. The material (PETG) is strong enough, the finish is professional, and the functionality is identical to injection molded parts.

Replacement parts and spare parts

One of the most underrated applications is 3D printing replacement parts. Machines whose manufacturer no longer exists, parts that are discontinued, or simply parts that take too long to arrive - 3D printing solves it.

A client in the food industry needed a critical machine part that normally had an eight-week lead time. We reverse-engineered the part and delivered it within three days. The machine was running again, and the client now orders their spare parts from us regularly.

Production tools and aids

Jigs, fixtures, molds, and measuring tools - all perfect for 3D printing. These aids improve production processes but are often too expensive to make via traditional methods.

An assembly company had custom jigs made that sped up assembly of a specific product by 30%. The jigs cost a fraction of what metal equivalents would have cost, and were operational within a week.

Understanding 3D printing economics

To determine when 3D printing makes sense, you need to compare total costs - not just unit price.

With traditional manufacturing:

- Tooling/mold costs (one-time, often high)

- Unit price (low at high volumes)

- Tooling lead time (weeks to months)

- Change costs (new tooling required)

With 3D printing:

- No tooling costs

- Unit price (constant regardless of volume)

- Lead time (days)

- Change costs (only a new print file)

The crossover point varies by part, but as a rule: for quantities under 500-1000 units, 3D printing is often more economical. With frequent design changes, this crossover shifts to even higher quantities.

Getting started with B2B 3D printing

The step to 3D printing doesn’t have to be big. Many businesses start with a single project to learn the technology, then build from there.

At 3Dennis, we make this step as easy as possible:

- No minimum orders

- Quotes within hours

- Advice on design and material

- Flexible lead times as needed

- Dedicated point of contact

Want to discover what 3D printing can mean for your business? Request a quote or send your design for a quick assessment. We’re happy to explore the possibilities with you.

Keep reading

Batch 3D Printing for Businesses: Producing Small Runs Efficiently

How does batch 3D printing work? Discover the advantages of series production with 3D printing for businesses. From 10 to 1000 pieces - efficient and affordable.

End-Use Production Parts: When 3D Printing Replaces Traditional Manufacturing

Discover how businesses use 3D printed end-use parts in production. From material advances to real cost benefits — why 3D printing is no longer just for prototypes.

Custom Enclosures: 3D Printing vs Injection Molding - The Honest Comparison

When do you choose 3D printed enclosures and when injection molding? A practical comparison of costs, lead times, and quality for businesses.

Need help with your project?

Contact us for custom 3D prints or B2B services.